Swedish clothing brand, Asket, has utilised the power of product information to educate its customers about the environmental footprint of their purchases while encouraging them to make more thoughtful, sustainable choices, in partnership with Akeneo.

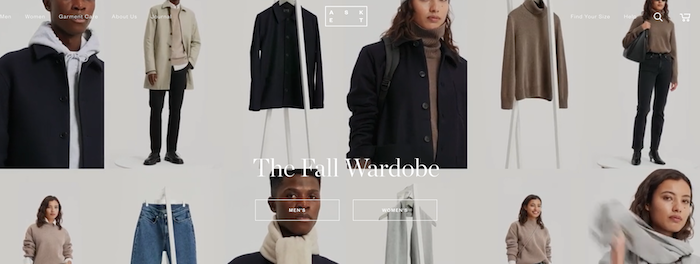

Asket was founded in 2015 with a clear mission to craft timeless and essential garments and unlike traditional fashion brands that produce multiple collections each year, Asket offers a permanent collection. This minimises waste and encourages consumers to invest in high-quality pieces that last. Asket’s single permanent collection serves as a vehicle for what it calls The Pursuit of Less – a commitment to reducing extraction, exploitation and waste while promoting longevity and responsibility by emphasising the natural resources and human labour involved in the production of its garments.

Alongside its direct-to-consumer (DTC) digital site, in Stockholm, Sweden, Asket has both a flagship store and resale and repair outlet, The Asket ReStore, which sells reconditioned garments that have been repaired ensuring they aren’t incinerated or sent to landfill. Central to its goal of positively changing the global apparel industry are transparency and consumer education explains Vidar Trojenborg, the head of technology and data at Asket. “When we set out to change the fashion industry, we realised that in order for our customers to appreciate the true value and cost of producing a garment, we needed to bring them along on the journey,” he commented.

Product information is a foundational strategy Asket utilises to educate customers about the environmental footprint of their purchases while also addressing critical sustainability challenges, such as size sampling and returns.

By utilising Akeneo’s PIM solution, Asket can store, organise and distribute its vast amounts of product data to create fully content-rich product display pages. These include both traditional product information alongside transparent sustainability information, detailing each garment’s complete cost breakdown and environmental impact, ensuring that every item’s story is accurately conveyed to the consumer.

“Before we had a PIM, we stored all of this information in Excel and Google Sheets, which was cumbersome and inefficient. With Akeneo, we can now manage and share product data seamlessly,” commented Trojenborg.

For every garment, Asket discloses its supply chain traceability, environmental footprint and cost structure, including information on all factories and production facilities used to create its clothing, alongside details, such as average salaries, shift lengths and imagery of the working conditions, used in its manufacturing and sourcing processes.

“Building to last – both in terms of products and business strategies – requires thinking about the entire lifecycle, from design to production to end-of-life,” concluded Trojenborg.

Share